|

| Introduction |

Specifications | Construction |

Electronics | Supplies | Photos

| PLUTO+ | Pluto-2.1 |

PLUTO-2.1 Construction

The information presented here is supplemental to Revision

4/27/05 of the PLUTO Construction Plans. It provides the necessary

additional detail for constructing PLUTO-2.1. Ignore

the earlier Pluto-2 information on the owner-support page.

A - Replace the

Peerless woofer/midrange drivers with Seas L16RN-SL

(H1480-08) available from www.madisound.com

.

Since the driver has a circular mounting rim it is not necessary to use the

cardboard gasket described on page 11. Stuff the 4" pipe uniformly with

Acoustastuf by adding 85 gram for a total of 200 gram.

The tweeter's surround plane should be set back 3/8 inch from the edge of the

woofer's basket rim.

B -

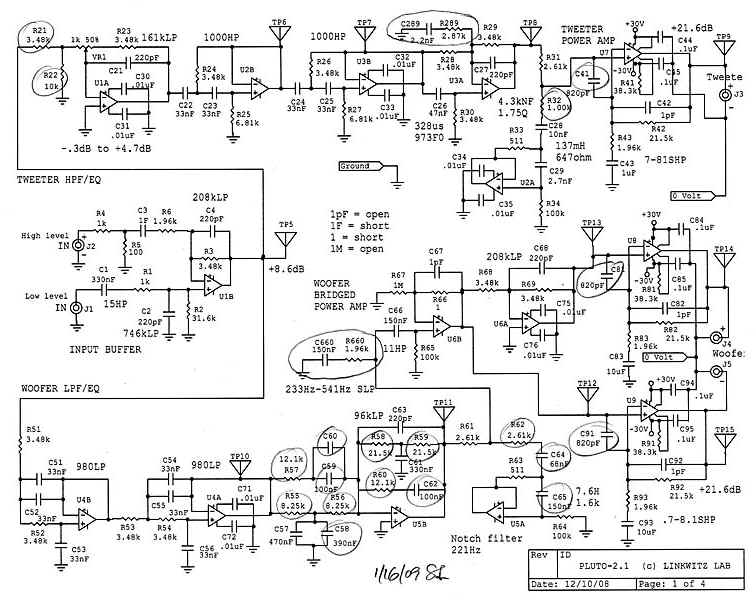

Crossover/Equalizer/Amplifier electronics

Use the updated material list Pluto-2.1-material list.xls

Components with new values and

the two added R-C networks are circled on the schematic and in red on the layout

diagram.

Tweeter channel gain2.1

R21 3.48k

R22 10k

Tweeter high frequency boost

R289 2.87k

C289 2.2nF

Tweeter notch filter2.1

R32 1.00k

Woofer boost

R55, 56 8.25k

R57, 60 12.1k

R58, 59 21.5k

C58 390nF

C59, 62 100nF

C60 open

C61 330nF

Midrange down shelf2.1

R660 1.96k

C660 150nF

Midrange notch filter2.1

R62 2.61k

C64 68nF

C65 150nF

Amplifier stability control

C41, 81, 91 820pF

2.1 = changes

to Pluto-2 |

|

The leads of C64 and C65 have to be bend so that the two

capacitors fit into the pcb next to each other.

Tweeter high frequency boost R-C network |

Midrange R-C shelf and notch filter components |

The three power amplifier IC packages are mounted to an

Aluminum sheet metal piece and individual heat sinks. Thermal compound is

applied to the individual heat sinks and the three IC packages. The circuit will

work without the sheet metal heat sink but the amplifiers can get very hot and

shut down protectively at high volume levels. Adding the sheet metal will

increase the amplifier reliability and avoid thermal shut-down.

2.0" tall heat sink to fit the original PLUTO base |

2.75" tall heat sink for the alternative PLUTO-2.1 base |

| The 2.75" height of

the metal piece has to reduced to 2.0" to fit the PLUTO base |

|

Electrical test chart

Input

voltages greater that 0.645 V at 10 kHz and above will cause clipping at TP9.

The input to output frequency response without the drivers

connected and measured with a 10x attenuator is the most important description

of the electronic module. It should match within +/-0.5 dB.

The spot frequency checks with the table above are primarily intended to find

errors in construction.

C - Alternative

cabinet construction

A larger base for easier access to the electronic module and improved heat

transfer from the power amplifiers may be desirable.

Also the rubber coupler for mounting the woofer/midrange driver can be replaced

by a ring of wood slats that are screwed into a standard 4" pipe coupler.

Place a strip of 3/8" wide and 3/16" thick foam

tape as gasket under the woofer/midrange basket rim before screwing the driver

to the ring of wood slats. The 4" pipe should be stuffed uniformly with 200

gram of Acoustastuf. When upgrading from an existing Pluto-2 it is not necessary

to remove the driver to add stuffing material since the audible effect is

minimal. Check for air leakage by applying a 10 Hz, 10V signal to the

woofer/midrange speaker cable. If you hear puffing noise, then find its location

and seal the leak with GE Silicone II Household Glue. There should be a pin hole

leakage path left open so that the cone comes slowly back out, when slowly

pushed in.

The maximum amount of stuffing material in the pipe behind

the tweeter is not critical, but should be at least as specified.

| Part |

Name |

Material |

Size (inch) |

Quantity |

| A |

Top & Bottom plate |

3/4" plywood |

10.5 x 6.5 |

2 |

| B |

Legs |

3/4" plywood |

5.5 x 2 |

4 |

| D |

Amplifier Mounting plate |

1/4" plywood |

10.5 x 6.25 |

1 |

| E |

Front trim plate |

1/8" hardboard |

8.25 x 3 |

1 |

| G |

Side trim plate |

1/8" hardboard |

10.5 x 3 |

2 |

| C |

Pipe bracket |

5/16' plywood |

3 x 1-3/8 |

4 |

| F |

Pipe bracket base |

3/4" plywood |

3 x 1-7/8 |

1 |

| P |

Barrel plate |

1/2" plywood |

4 x 1-3/8 |

12 |

| S |

4" Pipe Coupler |

ABS or PVC |

5" outside diameter |

1 |

| K |

Woofer pipe |

4" ABS or PVC |

27" long, 4.5" OD |

1 |

| L |

Tweeter pipe 1 |

1.5" ABS or PVC |

30" long |

1 |

| H |

1.5" PVC Pipe coupler |

PVC |

3" long |

1 |

| J |

Coupling insert |

1.5" ABS or PVC |

2" long |

1 |

| M |

Tweeter pipe 2 |

1.5" ABS or PVC |

4.25" long |

1 |

The internal height of the base is 3.5".

|

Mounting plate for the

electronics Note that the electronic module

described under B above works correctly also for the alternative cabinet

construction.

|

| Introduction |

Specifications | Construction |

Electronics | Supplies | Photos

| PLUTO+ | Pluto-2.1 |

|